The current status of and future trends in heat pump technologies with natural refrigerants

1. Introduction There is currently an urgent need to develop technologies for the use of environmentally-friendly refrigerants that are low in global warming potential (GWP). Mitsubishi has already developed and commercialized refrigerators and heat pump water heaters that use environmentally-friendly natural refrigerants. We are persisting with R&D efforts aimed at commercialization of next-generation heat pump systems that use natural refrigerants. The following paragraphs introduce the current status and future aspects of Mitsubishi’s technological development.

2. Trends in the Regulation of Refrigerants

The trends in the regulation of the use of HFC (Hydro Fluorocarbon) refrigerants currently used in air-conditioning systems, heat pump water heaters and refrigerators are described below.

(1) Emission control of greenhouse gas after enforcement of the Kyoto Protocol

Conforming to the 1994 UN Framework Convention on Climate Change for the prevention of global warming, the Kyoto Protocol was adopted as a concrete measure to control greenhouse gas emissions (in 1997). Thereafter, with the ratification by Russia, the Kyoto Protocol was enforced in 2005. The relevant industrialized nations are required to reduce greenhouse gas emissions by 6% (down from 1990 levels) in Japan for example during the first commitment period (2008 to 2012). Flon’s substitutes are designated as greenhouse gases to be reduced in accordance with the Protocol because they have a high GWP and their emissions are expected to be reduced by maximum efforts from the participating nations.

(2) Outline of fluorinated gas regulations in Europe (1)

The target of the regulations is to confine or reduce the emissions of fluorinated warming gases, HFC, PFC (perfluorocarbon) and SF6 (sulfur hexafluoride) which are targeted by the Kyoto Protocol. For purposes of confining fluorinated gases, some requirement items related to fixed-type refrigeration, air-conditioning and heat pumps became compulsory, effective July 4, 2007, with respect to gases that have a global warming potential of 150 or higher.

3. Trends in Flon Elimination Technologies for Heat Pump Systems

3.1 Natural refrigerants as flon-free refrigerants

Fluorocabon refrigerants currently used in heat pump systems with vapor compression refrigeration cycles are safe, highly efficient and can be used extensively. New heat pump system designs are making such refrigerants increasingly suitable for use.

The required characteristics of refrigerants a decade or so ago did not include requirements associated with global environmental conservation (such as protection of the ozone layer and prevention of global warming), although requirements against toxicity and flammability were specified. Today, with the prevention of global warming being a mandatory issue, materials with little or no influence on the global environment are required most, with the requirement of low toxicity or flammability being emphasized less than it was before.

Because the refrigerants currently being used are considered to have a considerable influence on global warming if emitted into the air, it is necessary to reuse or destroy them without atmospheric emission. However, as things stand, it is very difficult to meet these requirements.

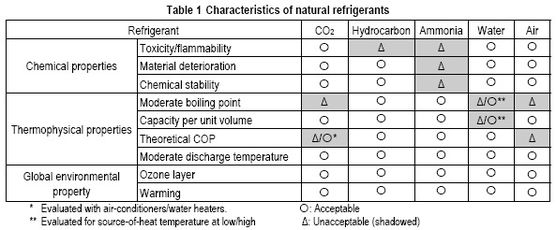

The focus has gradually turned to natural refrigerants regarding global environmental preservation. At present, CO2, hydrocarbons (propane, propylene, etc.), ammonia, water, and air are considered as possible flon-free refrigerants. Of the potential candidates mentioned above, air is different from the others as applied to the vapor compression refrigeration cycle, however, it is included from a functional point of view. Although these natural refrigerants are excellent in terms of global environmental preservation, they possess shortcomings in chemical characteristics and/or thermophysical properties, as shown in Table 1. We have to tackle such difficulties and find solutions, in terms of both hardware and software.

3.2 Targets of R&D

Looking at CO2 and hydrocarbons in particular, special attention must be paid to the following two characteristics for their use as refrigerants in heat pump systems.

CO2: because it has a low boiling point, systems will have to be designed to endure service pressures of 100 to 150 atmospheres, as the refrigerant exceeds the critical point.

Hydrocarbons: because hydrocarbons are flammable, it is necessary to take measures to reduce in the amount of refrigerant, to prevent leakage, and to eliminate the sources of ignition for the elimination of accidents when handling the material for repair and disposal after use.

Apparatuses that use these refrigerants have already been marketed. The target of R&D activities in this sense is to improve the performance of existing apparatuses or to expand the application field by developing new types of apparatuses.

4. Development of Flon-free Heat Pump Systems

The following descriptions refer to an outline of R&D activities aimed at developing flon-free heat pump systems that are underway as part of the NEDO (New Energy and Industrial Technology Development Organization) project and the challenges and present circumstances related to major element devices incorporated in heat pump systems.

4.1 Participation in the NEDO development project for next-generation, flon-free apparatuses

Mitsubishi has participated in the two NEDO projects described below to promote the basic technological development of next-generation, flon-free apparatuses.

(1) Double-stage compressor heat pump water heaters for cold district

We conducted an R&D program (FY2005 to FY2006) under the theme of “double-stage compressor heat pump water heaters using CO2 refrigerant for cold district” in compliance with the target of “improvement in efficiency and down-sizing of high-efficiency water heaters” of the Strategic Development of Energy Conservation Technology Project.

The ratio of suction pressure (low pressure) of the compressor to the discharge pressure (high pressure) is large and subjects the compressor to harsh operatingconditions in cold district where the lowest temperatures range from -10 to -20°C, which theoretically lowers both the water-heating capacity and the coefficient of performance (COP). For this reason, this R&D focused on the improvement of the water heating capacity and COP. The performance and reliability were to be improved by a mechanism that includes the compression stroke divided into two stages and the refrigerant injection at intermediate pressure. In addition, improvement in the thermal insulation performance of the hot-water tank and development of a high-efficiency gas cooler (heat exchanger) were also included in R&D activities for a higher COP.(2)

(2) Multi-air conditioners for buildings

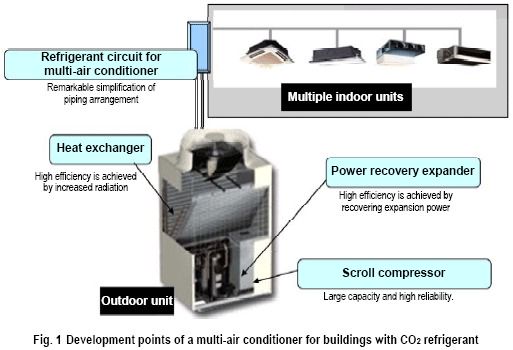

We have also been developing multi-air conditioners for buildings using a CO2 refrigerant as part of the development of Non-fluorinated Energy-Saving Refrigeration and Air Conditioning Systems for Business Use under the “Development of Non-fluorinated Energy-Saving Refrigeration and Air Conditioning Systems (FY2005 to FY2007)”.

This development program is characterized by aiming at high performance systems through the combination of a recovery function for cooling exhaust heat, an energy reutilization function with a power recovery expander and gas cooler radiation mechanism that saves energy by making use of CO2 characteristics. The development target is to achieve an annual operating efficiency equal to that of the current models, or higher.

Figure 1 shows the major component devices and their characteristics.

4.2 Technological challenges of developing CFC-free refrigerant heat pump component devices

(1) Expansion power recovery circuit

One of the means of recovering expansion power is with an expander. An expander is driven by the expansion of high-pressure refrigerant. The resultant driving force is used for compression or other types of power. The most difficult challenge with this mechanism is to control the operating conditions, such as the rotating speed of the expander and the compressor, for maximum power recovery.

(2) Heat exchangers

1) A gas cooler for water heaters

During heat exchange within the supercritical range, the temperature of CO2, which is incondensable, gradually lowers while passing heat to water, thus there is no range where the temperature remains constant. For this particular characteristic, a gas cooler for water heaters can affect ideal countercurrent heat exchange with little temperature difference between the water and the refrigerant. Mitsubishi employed a twisted-tube gas cooler (2) in which a CO2-flow pipe is wrapped around the slot in the twisted water piping. Mitsubishi will improve the pipe diameter, joining method, and insulation method for improved performance of the gas cooler.

2) A gas cooler for air-conditioners

Most gas coolers for air-conditioners employ a single-direction heat exchange method for the air. It is difficult to use a complete counter-flow type method like that employed in water heaters. However, with a structure containing a number of microchannels laid out in parallel to provide counterflow channels for heat exchange with the air, the efficiency of the gas cooler can be improved.

(3) Compressor

When using CO2 as natural refrigerant, compared with the current HFC refrigerant, the discharge pressure of the compressor nearly triples to 10 MPa and the rate of discharge pressure to suction pressure almost triples. As a result, internal losses in the compressor such as leakage loss and mechanical loss increase. Naturally, it becomes necessary to improve the performance against loss and also reliability, by increasing the structural strength as well as wear/friction durability.

Mitsubishi has developed small-capacity rotary type compressors (3),(4),(5) for household heat pump water heaters. In addition, for large-capacity applications, the development of a CO2 scroll compressor to be used in business-use heat pump water heaters or building-type multi-air conditioners is underway.

(4) Power recovery expander

Since the expansion enthalpy drop in CO2 circuits is much larger than that of an HFC refrigerant, recovery and reuse of expansion power are effective, resulting in improved efficiency. Power recovery expanders with the same basic structure as a compressor are being developed at present. To improve efficiency, special attention is being paid to the reduction of internal leakage loss and friction loss.

5. Conclusion

This paper outlined Mitsubishi’s current R&D activities related to technologies for natural refrigerant air-conditioners. Mitsubishi will improve the efficiency and reliability of products equipped with the technologies discussed above.

References:

(1) Directive 2006/40/EC of the European Parliament and of the Council (2006).

(2) T. Okada: CO2 Refrigerant Heat Pump Water Heater “ECO CUTE”, Mitsubishi Technical Report, 81, No.3, pp. 185-188, 2007.

(3) H. Maeyama et al.: “Development of a Compressor for CO2 Heat Pump with a Single Rotary Mechanism,” International Compressor Engineering Conference at Purdue (2006), C056.

(4) H. Maeyama: Development of a Compressor for CO2 Heat Pump Water Heater with a Single Rotary Mechanism, The International Symposium on New Refrigerants and Environmental Technology 2006, pp. 217-222.

(5) H. Maeyama: Rotary Compressor for CO2 Heat Pump Water Heaters, MitsubishiTechnical Report, 81, No. 3, pp. 189-192, 2007.

By Naoki Tanaka, Living Environment & Digital Media Equipment Group, and Satoru Kotoh, Advanced Technology R&D Center

Source: Mitsubishi Electric’s R&D Department