Acoustical considerations for large rooftop units

Rooftop HVAC equipment provides enticing features for the design engineer and cost advantages for the owner. Fans, ventilation equipment, a heat source, compressors, condenser, and controls are assembled in a compact unit ready for installation on a roof curb. Manufacturers assemble, test, and rate the entire package as a system. The advantage of locating the unit on the roof frees up floor space in the building.

The convenience of packaged

equipment has driven a demand for

increasingly larger units. Packaged

rooftop equipment is now available

from several manufacturers in sizes up

to and beyond 150 tons. The larger

units' design has also been updated to

meet industry demand for improved

efficiency and indoor air quality.

Greater flexibility in fan choices,

equipment options, and unit

configuration is also becoming

available.

With these larger units, many factors

need to be considered in the design of

the building, such as increased

structural support, larger electrical

service, etc. Unfortunately, the

increased sound levels produced by

these units are sometimes overlooked.

Following a fixed set of acoustical

practices used with smaller units may

not sufficiently attenuate the increased

sound levels of the new larger units.

Large packaged rooftop units can be

installed without creating noise problems

in the occupied spaces, but not without

appropriate consideration. An acoustical

review using the source-path-receiver

acoustical model (see sidebar, p. 3

"Defining an Acoustical Model") early in the

design process is critical to achieving the

desired sound levels.

The discussion that follows:

• Illustrates how an acoustical analysis

affects design decisions and helps the

installation succeed in terms of first cost

and occupant satisfaction.

• Outlines general and specific acoustical

considerations for very large rooftop

units.

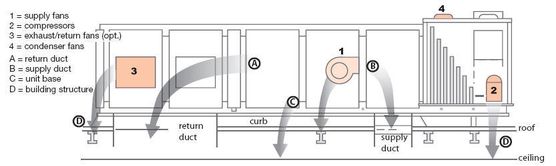

Figure 1. Large rooftop: Four types of sound paths

Acoustical Analysis,

Step by Step

An acoustical analysis consists of five

basic steps:

Step 1: Set acoustical goals for the

finished space. It is critical to establish

the acoustical goals for the finished space

at the outset of any HVAC project. There

are always implicit, often subjective,

expectations for the background sound

level in occupied spaces. It is much easier

to produce a successful installation if you

understand these expectations before

designing the installation. The risk involved

in waiting until the unit is installed is

considerable because the cost of quieting

an installed unit always exceeds the cost

of applying the same treatment during

installation.

Also be aware that once a unit is installed,

some changes, e.g., switching to a

different fan size, will not only be

expensive but could affect the unit’s UL

rating.

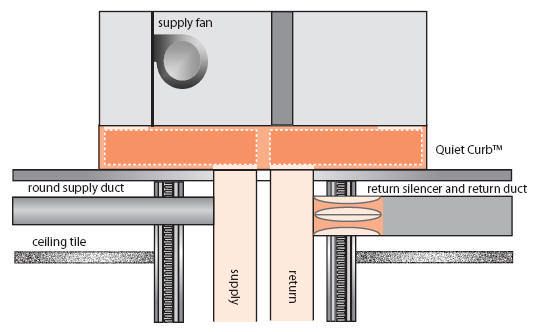

Figure 2. High level of path attenuation

Remember these three points when

defining desired sound levels:

1. As a general rule, lower sound levels

cost more to achieve.

2. All spaces in the building do not have

the same sound requirement; a lowcost,

quiet installation takes advantage

of this point.

3. Successful acoustics requires a team

effort. The team should include the

owner, engineer, architect, equipment

manufacturer, and contractor.

Sound goals will vary depending on how

the space is used. Once the sound

goals are understood, state them using

an appropriate descriptor such as NC

(Noise Criteria) or RC (Room Criteria).

Step 2: Identify each sound path and

its elements. Large rooftop HVAC

installations have four types of paths

(Figure 1, p. 2):

1. Airborne sound follows the airflow

path. Supply airborne sound travels the

same direction as the supply air. Return

airborne sound travels against the

airflow direction. Airborne sound also

includes sound generated by the

ductwork and diffusers.

2. Breakout sound passes through

duct walls into the plenum space, then

through the ceiling and into the room.

3. Roof transmission sound passes

through the roof deck (both within and

outside the roof curb), plenum space,

and ceiling into the room.

4. Structure-borne sound differs from

the other sound paths in that it is

vibrational energy transmitted through

the framework of the building. This

energy may come directly from the

vibration of the sound source or from

airborne sound energy transferred to

the structure.

Step 3: Perform a path-by-path

analysis. Once each path has been

identified, individual elements can be

analyzed for their contribution. For

example, the supply airborne path

includes various duct elements (e.g.,

elbows, straight duct, junctions,

diffusers) and a room-correction factor.

Algorithms available from ASHRAE can

calculate the acoustical effect of each

duct element. The effect of changing

an element (e.g., removing the lining

from a section of ductwork) can be

examined. A software tool like the

Trane Acoustics Program™ (TAP)

simplifies this process.

This step typically entails at least two

iterations for each path. The first pass

establishes the acoustical performance

of the initial design. Subsequent

passes determine the effect of adding

various acoustical treatments.

Step 4: Sum the results to determine

the acoustical performance of the

installation. The sound level at a

receiver location is the sum of all the

sound paths for that location, both

from the rooftop unit and from other

sound sources. After the contributions

of the individual paths are calculated,

add them together to determine the

sound level at the receiver location. If

the sum exceeds the goal, another

round of path attenuation calculations

is required.

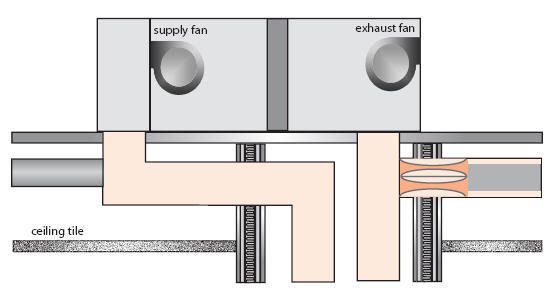

Figure 3. Low level of path attenuation

Step 5: Compare the summations

with the acoustical goals in the

context of the project budget. Once

a design meets the acoustical goals for

the project, everyone on the team

must understand the work and costs

required to implement the design. It

may also be prudent to review the cost

of meeting the acoustical goals and

reconsider equipment options that

were initially rejected due to cost.

Additional guidance on creating a

rooftop sound analysis can be found in

the Trane application manual and

ASHRAE Journal article listed in the

reference section.

Specific Considerations for

Very Large Rooftops

As rooftop unit size increases, building

and duct construction details play a key

role in determining the sound levels in

the occupied space. Review of

generalized acoustical models for large

rooftop applications indicate that the

three critical sound paths are return

airborne, return breakout, and supply

breakout. The models also show that if

acoustics are not considered, an

application can have sound levels that

are too high. However, acceptable

sound levels in the occupied space can

be achieved with proper attention to

unit selection and application details.

This section uses a generalized

acoustical model to show how both

unit and application choices impact the

potential NC in an occupied space. As

described in the previous section, an

accurate estimate of sound pressure in

the occupied space requires a unique

acoustical analysis for each application.

The NC values in this section are based

on a generalized model and do not

indicate what the sound will be in any

particular application.

Quiet the Source. One way to lower

the sound level in the occupied space

is to reduce the sound produced by the

rooftop unit. Operating conditions, fan

selection, optional equipment, and

cabinet choices all have an impact on

the amount of sound produced by the

rooftop unit.

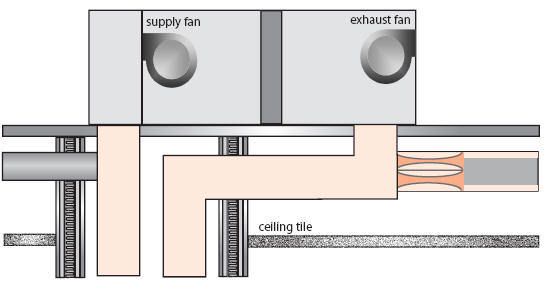

Figure 4. Low level of path attenuation

Solid Surfaces. Some rooftops come

standard with solid double-wall

construction throughout. This helps

prevent dirt and moisture from

adhering to the surfaces but makes the

surfaces less absorptive to sound.

For applications that do not require all

solid surfaces in the airstream, one or

more sections of the unit may be

available with a sound absorbing lining

(either with or without a perforated

plate) and a moisture barrier to

separate the lining from the airstream.

Units rated following ARI 260 test

methods indicate that the addition of

lining can result in a sound reduction

on the order of 4 to 6 dB in the critical

125 Hz octave band.

Fan Configuration. Units may be

configured with supply fan only, supply

and exhaust fan, or supply and return

fan. Although unit configuration isn't

generally based on acoustical

considerations, each choice has a

unique impact on sound produced by

the unit. If design flexibility allows,

check all available configurations to find

the one that is best for the application.

Supply Fan Only. This configuration

will have higher sound levels at the

discharge opening but relatively low

levels at the return. A supply fan only

configuration tends to perform well

overall because of the plenum

attenuation created by the heat and coil

sections on the discharge side, and

mixing and return sections on the inlet

side of the fan (see Figure 2).

The supply fan is the dominant sound

source in rooftop units. To help

attenuate the supply fan discharge

sound, consider using the largest

supply fan available in each tonnage

size. Larger fans run at a lower speed

and are typically quieter. Unit

selections have shown a 10 dB

reduction in the 250 and 500 Hz octave

bands at 32,000 cfm and 5" of fan

static for some fans. (Of course, unit

sound data is dependent both on fan

type and operating point, so check all

available fan selections for a particular

operating point.)

In general, moving to a larger fan will

lower the sound level for a given flow

and pressure drop. However, moving

to a larger fan may also move the fan

closer to a region where "acoustical

stall" occurs (see the sidebar "Acoustic

Stall").

The cost implication of changing the

fan type should also be considered. It

may be more cost effective to quiet the

unit/installation by another method.

Return/Exhaust Fan. In some cases

the addition of a return fan will lower

the discharge sound level; however,

return and exhaust fans increase sound

levels at the return opening. The model

shows that switching from a supply fan

only to a supply and exhaust fan

configuration increases the sound in

the occupied area below the rooftop by

3 NC. Switching to a supply and return

fan may result in an 11 NC increase

over the supply fan only unit. The

change in supply sound depends on

both the type and operating point of

the return/exhaust fan used.

Sound radiated from the return

opening comes from the inlet of the

supply fan plus the exhaust or return

fan. Adding a return fan may cause the

return airborne and breakout sound

paths to set the sound levels in the

occupied space. Return fans generally

result in higher sound levels in a space

than exhaust fans when the inlet to the

return fan is mounted directly above

the return ductwork. Sound from a

sidewall-mounted exhaust fan is

attenuated by the plenum effect of the

return section. Also, different fan types

and operating points may be used for

the two fans so the sound created will

be unique to each fan at each operating

point.

To lower the sound being transmitted

through the return air opening,

consider the following:

1. Review the sound data for return vs.

exhaust fan for your conditions to

determine which configuration

results in the lowest sound levels.

Also look at all fan options for each

configuration. Changing to a larger

supply and return fan size can have a

significant effect. A typical selection

showed switching to the larger

return fan at 27,000 cfm and 2" of fan

static will reduce the 250 and 500 Hz

bands by 4 and 5 dB respectively.

2. Consider using a horizontal

connection (if available) for the unit

return and running the return duct

over the roof before penetrating the

building. Running the return duct

over the roof has several

advantages:

• Low frequency sound will break

out of the duct walls to the

outdoors, thereby reducing the

sound entering the building.

• Lining the duct run on the roof will

provide attenuation at the mid and

upper frequencies.

• The duct penetration can be

moved to a non-sound sensitive

area of the building.

Quiet the Sound Paths. Quieting the

unit helps, but the greatest acoustical

benefits come from looking at how the

unit is integrated with the building.

Changing the installation to attenuate

the critical sound path(s) can have a

dramatic effect on sound levels in the

occupied space.

Location. Locating a large rooftop unit

over a sound-sensitive area will either

result in unacceptably high sound

levels in the occupied area or add

considerable cost to prevent the sound

produced by the unit from reaching the

occupants. Consider locating the unit

over a non-sound sensitive area, even if

it means running the supply and return

ducts over the roof. External runs of

duct can provide attenuation of the

supply and return airborne sound

before the roof penetration is made.

Roof Structure. Supply duct breakout

has commonly been the critical sound

path for rooftop units, but problems

with roof transmission are on the rise.

This is perhaps due to an increased

awareness and attention to attenuating

the discharge path, but it may also be due to the increased use of lightweight

roof structures.

Sound radiated from the compressors,

condenser fans, exhaust fans, and the

casing of the unit will impinge on the

roof surface surrounding the unit. A

lightweight roof (metal deck with

insulation and ballast) provides minimal

resistance to the transmission of

sound.

The poor transmission loss

characteristic of roofs often becomes

apparent when taking sound readings

on problem jobs. With all sound

producing equipment off, place a radio

at moderate volume on the roof near

the unit and go inside and listen. If you

can hear the radio, roof sound

transmission is likely to be a problem.

Increasing the transmission loss of the

roof generally means adding mass to

the roof--typically a concrete slab--

around the unit. Thickness and area of

the slab are dependent on how much

transmission loss is required to meet

the sound goals for the job.

Also avoid unit placement on a flexible

roof structure that will transform

vibration from the unit into sound that

radiates into the building. As with all

rooftop units, placing the unit in a

location over a column or other rigid

support element will minimize this

problem. Proper support is especially

important for larger units because of

the increased mass and vibration

energy due to larger compressors and

fans, and high airflow.

Duct Chase. When a large rooftop unit

serves several floors of a building via a

duct chase, properly positioning the

unit over the chase will have a dramatic

effect on the sound levels in the

occupied areas near the unit.

Figure 2 shows a construction that will

provide a high level of path attenuation.

A special curb is used that provides

unit attenuation and brings the supply

and return openings closer so they can

be matched up with the chase

opening. Notice that a short run (height

of one floor) of return duct is installed

inside the chase; this provides some

additional return breakout transmission

loss that lowers the sound levels in the

chase.

Return air openings at the floors are

supplied with a silencer and a short run

of lined return duct to provide

additional attenuation and move the

return airborne sound away from the

shaft wall. Round duct is used for the

supply to reduce duct breakout near

the chase wall. The generalized model

shows that removing the short run of

return duct from the configuration

shown in Figure 2 results in an

increase of 10 NC for the supply fan

only unit and 12 NC for the supply and

exhaust fan unit.

Locating either the supply or return

opening over the chase and then

ducting the other opening to the chase

is not recommended (see Figure 3 and

Figure 4), except for jobs using a

poured concrete roof curb. Poured

concrete roof curbs are typically used

in conjunction with a concrete roof slab

to minimize roof transmission. With

the concrete curb, the supply opening

should be located over the shaft, as in

Figure 4, with the return duct run

inside the concrete curb to the shaft.

In all chase applications, it is important

that the chase is run all the way to the

roof deck and is sealed with acoustical

mastic to the roof deck. Supply and

return air duct penetrations though the

shaft wall must also be sealed to

prevent sound from leaking out of the

shaft.

General Considerations.

Operate the Unit as Designed. It is

quite common to overestimate the

system static pressure required to

achieve design airflow. This results in

the installation of larger motors and/or

higher fan rpm than required to

overcome the actual static pressure. To

compensate for the additional static,

the air terminal device balancing

dampers are more restricted than

necessary. These "over-aired" systems

waste energy and force the units to

generate excess sound.

To minimize noise, operate the rooftop

at the lowest possible pressure in the

duct. After installing the rooftop unit

and its associated air distribution

system, it must be properly air

balanced by qualified air balancing

technicians using calibrated air

measuring devices. The airside system

should be balanced to achieve the

desired airflow at all terminal outlets

while maintaining the lowest possible

fan rpm and system static pressure.

Utilizing the fan pressure optimization

control strategy is an excellent way to

achieve this on VAV systems. (See

"Energy Saving Strategies for Rooftop

VAV Systems", Engineers Newsletter

vol. 35--4, 2006.)

Proper Duct Design. The fans in the

rooftop unit are not the only sound

source in the HVAC system.

Aerodynamic noise is generated at

duct fittings, e.g., junctions, elbows,

diffusers, dampers, and take-offs. The

sound power levels generated at these

fittings are dependent on airflow

turbulence, fitting geometry, and

airflow velocity. Meeting the acoustical

goals for the job requires all sources of

sound to be considered.

Several guidelines for minimizing the

generation of aerodynamic noise are

available. The ASHRAE book, "A

Practical Guide to Noise and Vibration

Control for HVAC Systems" is a good

reference source for designing quiet

HVAC systems as are the ASHRAE

Handbooks. Careful duct design is

especially important at the discharge of

the rooftop unit. Air leaving a rooftop

unit tends to be turbulent; as a result,

pressure drop and generated sound

will exceed what is normally predicted

for fittings near the unit.

Closing Thoughts

Don't let noise ruin the advantages and

convenience of large rooftop units.

Review the acoustical goals for the

occupied space during the building

design process. Use an acoustical

analysis to identify and attenuate the

critical sound paths so the sound goals

for the job can be achieved. Yes, this

adds cost and takes time but not nearly

as much time and money as fixing a

problem job.

Artykuł pobrano ze strony: http://www.trane.com/CPS/Uploads/UserFiles/EducationalResources/admapn032en_0509.pdf